In brief

The advantages of a plate heat exchanger and tube heat exchanger combined

Vahterus is the innovator, trailblazer, and industry giant in Plate & Shell heat exchangers (PSHE). The fundamental structure of this heat exchanger involves a completely welded plate pack enclosed within a robust circular shell, rendering gaskets superfluous. This design enables Vahterus PSHE to amalgamate the optimal attributes of Plate & Frame heat exchangers and Shell & Tube heat exchangers.

Knowledge and experience

Vahterus’ all-welded Plate & Shell heat exchangers are developed and built based on extensive knowledge of heat transfer, laboratory tests and decades of practical experience in the market.

Compact solution

Vahterus’ Plate & Shell heat exchangers are on average about 60-70% smaller than a traditional Shell & Tube heat exchanger. This makes them extremely suitable for retrofitting, among other things.

About Vahterus

Inventor, pioneer, and market leader of the Plate & Shell heat exchanger

The Plate & Shell heat exchanger, invented by Vahterus, has become an integral part of the industry. Thanks in part to a global network of representatives, the Finnish company has sold tens of thousands of heat exchangers in recent years.

“…More than 25% of the staff have a background as technical structural engineers.”

Vahterus has a dedicated focus on providing customer-specific solutions, with most of their production facility geared towards this purpose. With a workforce of over 300 employees, of whom over a quarter have a technical design background, Vahterus is committed to continuous product development, from design to production, using automated technology and a broad knowledge of processes. To support this, a modern production site is crucial, and Vahterus’ factory now spans over 13,000 square meters, ensuring high-quality products for their customers.

Products

Gasket-free heat exchangers for the most critical applications

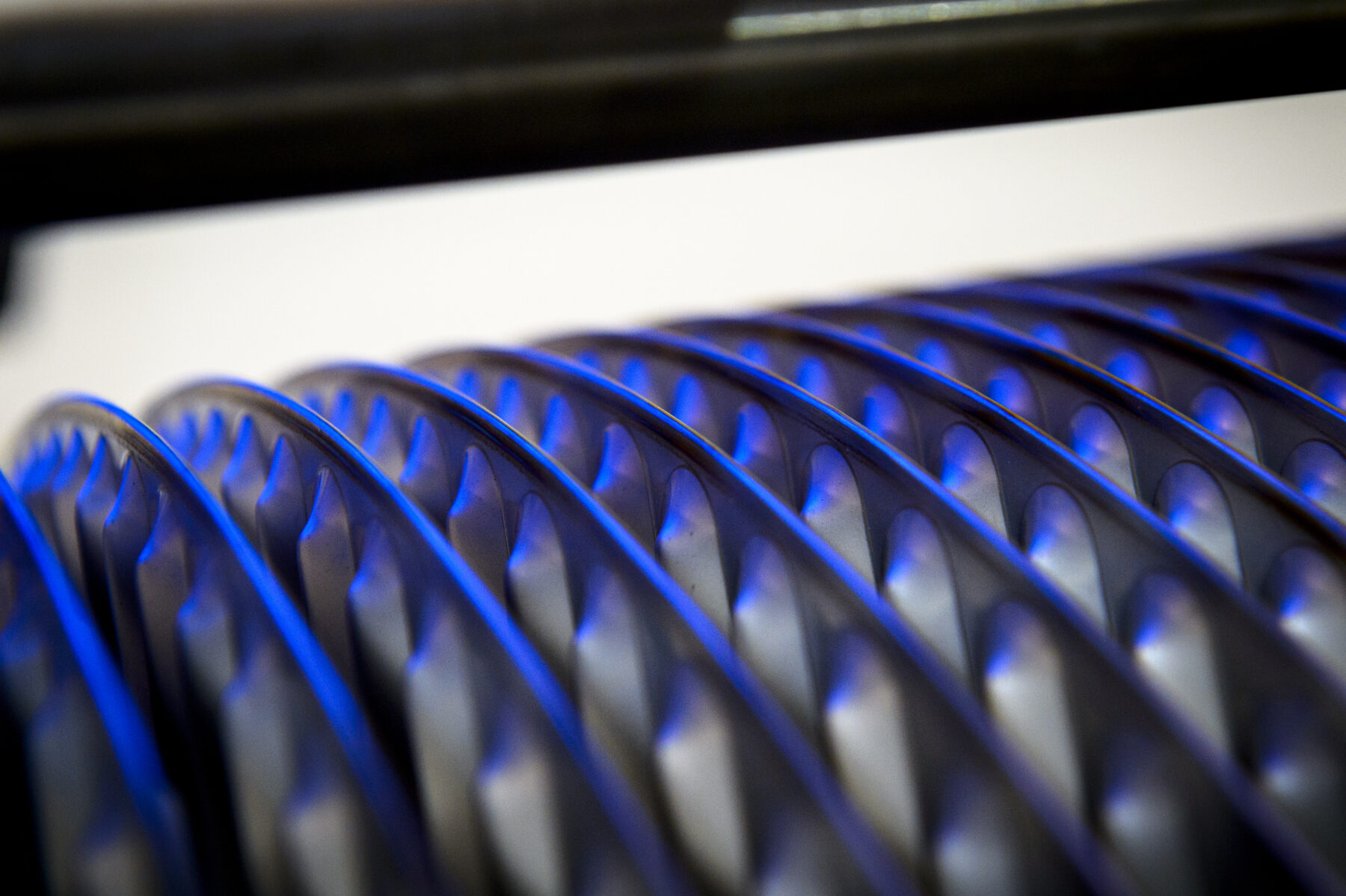

The core of the Vahterus heat exchanger consists of a fully welded plate assembly. The circular plates are welded together, with the openings between the plates acting as two separate channels for hot and cold media. The plate pack is then installed in a cylindrical outer shell. This eliminates the need for gaskets. Like the plate pack, the cylindrical shell is fully welded. The plate pack and the shell are not welded together, allowing them to expand and contract. The cold and hot media flow in opposite directions – one medium through the plate pack and the other around it in the shell – thus exchanging heat.

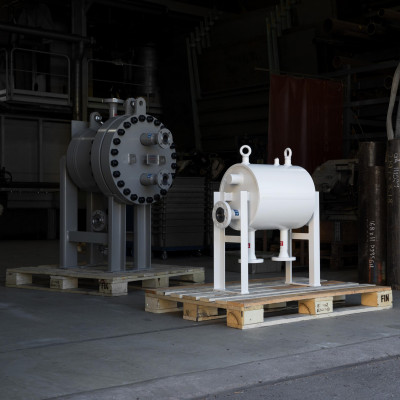

Welded PSHE

The fully welded Vahterus Plate & Shell heat exchanger consists of a plate pack enclosed in a fully welded shell to withstand high pressures and thermal shock.

Compact PSHE

This compact Vahterus Plate & Shell heat exchanger is designed to save even more space than a standard P&S and is easier to assemble at the customer’s site.

Openable PSHE

The Openable Vahterus Plate & Shell heat exchanger offers more flexibility as the plate pack can be pulled out of the shell for inspection or mechanical cleaning.

QUALITY REQUIREMENTS

We demand the same high quality as you

Vahterus and Kapp are familiar with the critical questions and stringent requirements from industry. All our products meet or can be supplied to design requirements and standards relevant to the industry you work in. These include:

Design codes

- AD-2000

- ASME VIII, Div. 1

- EN 13445

- Lloyd’s Register

- R.I.N.A.

- ABS Europe Ltd

- Bureau Veritas

- PD5500

- DNV GL Marine

- EAC

Quality requirements

- ISO 9001:2008

- ISO 3834-2:2005

- ISO 14001:200411

- PED module B+D

- PED module H

- ASME U and R Stamp

- OHSAS 18001:2007